Fiber vs CO2 vs UV Laser

Laser cutting and carving have changed the way materials are cut and carved today. Due to the accuracy, speed, and flexibility provided by laser engraving machines, these laser machines quickly became popular. The three most commonly used types of laser machines are CO2, fiber optic, and ultraviolet lasers. In this blog post, we will discuss each of these types, their advantages and limitations.

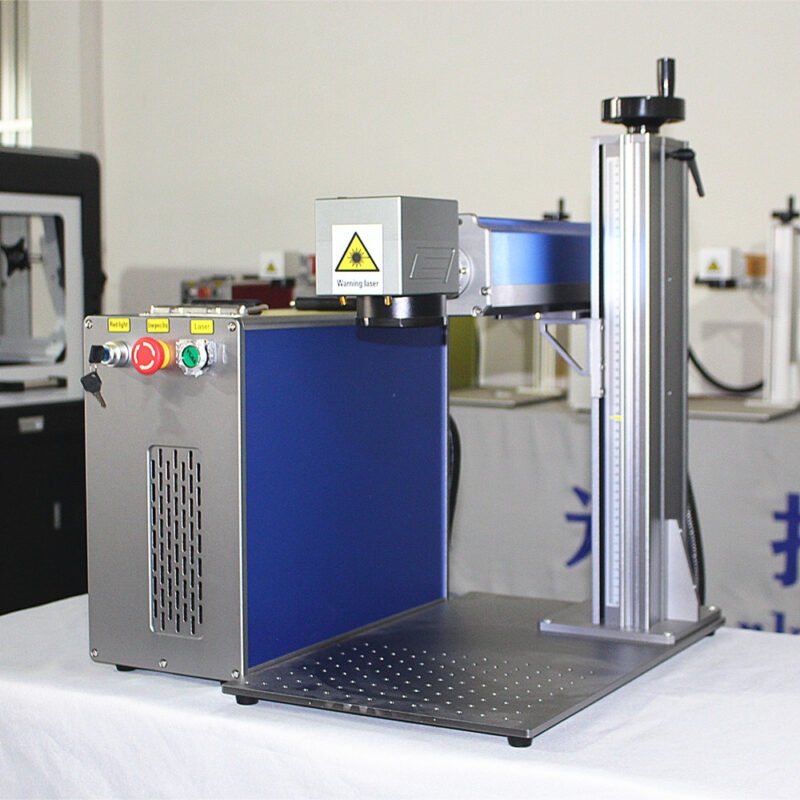

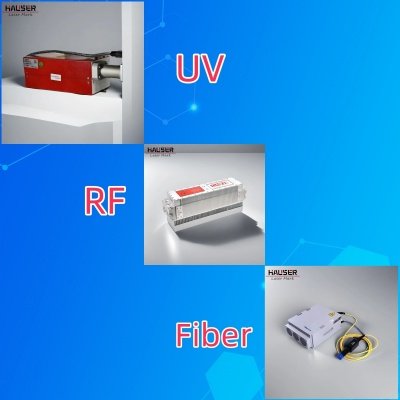

Fiber laser machine

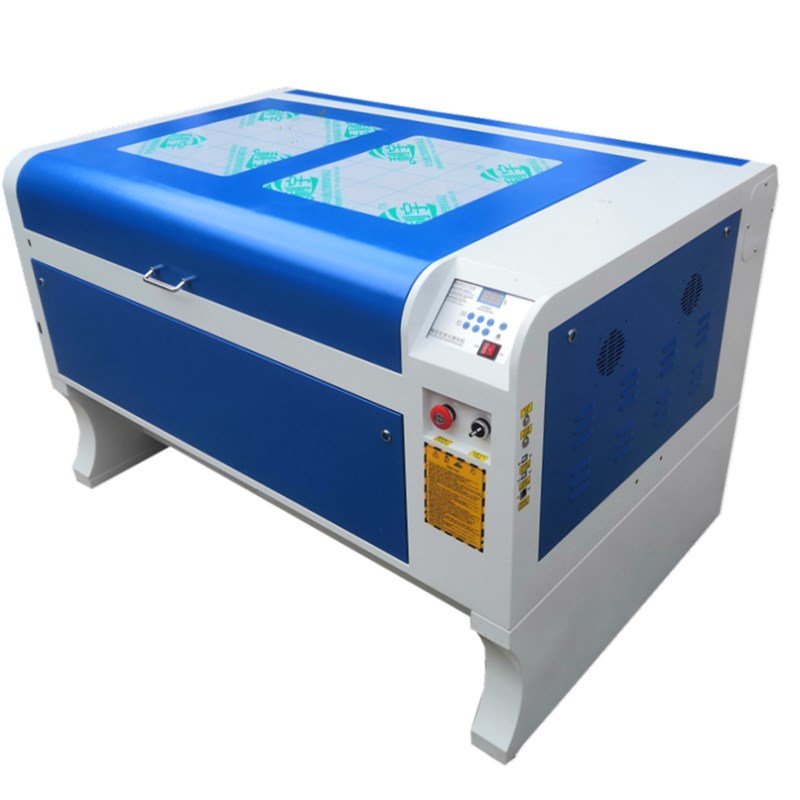

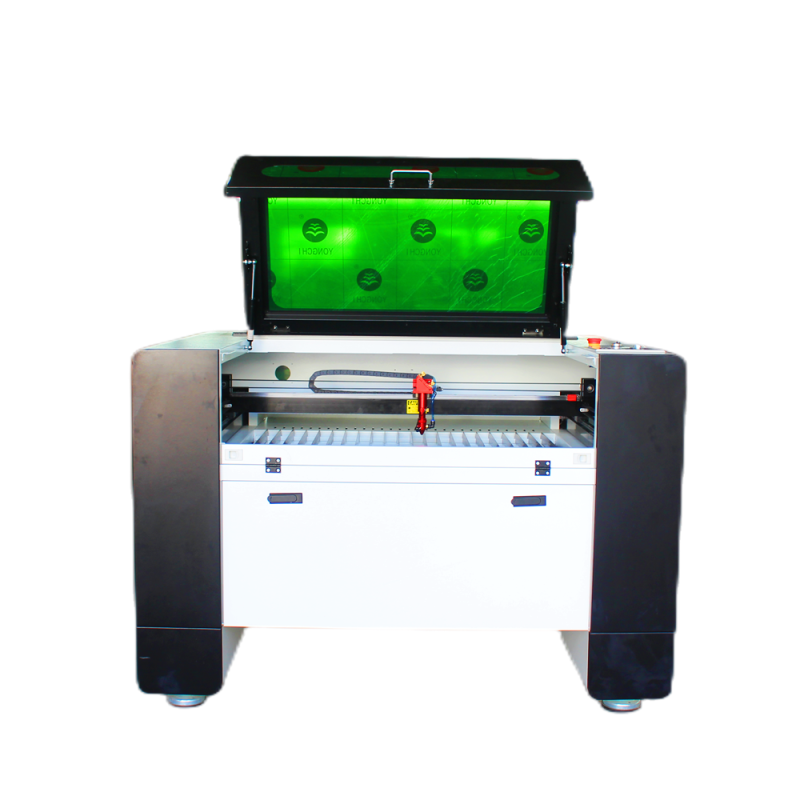

CO2 RF laser machine

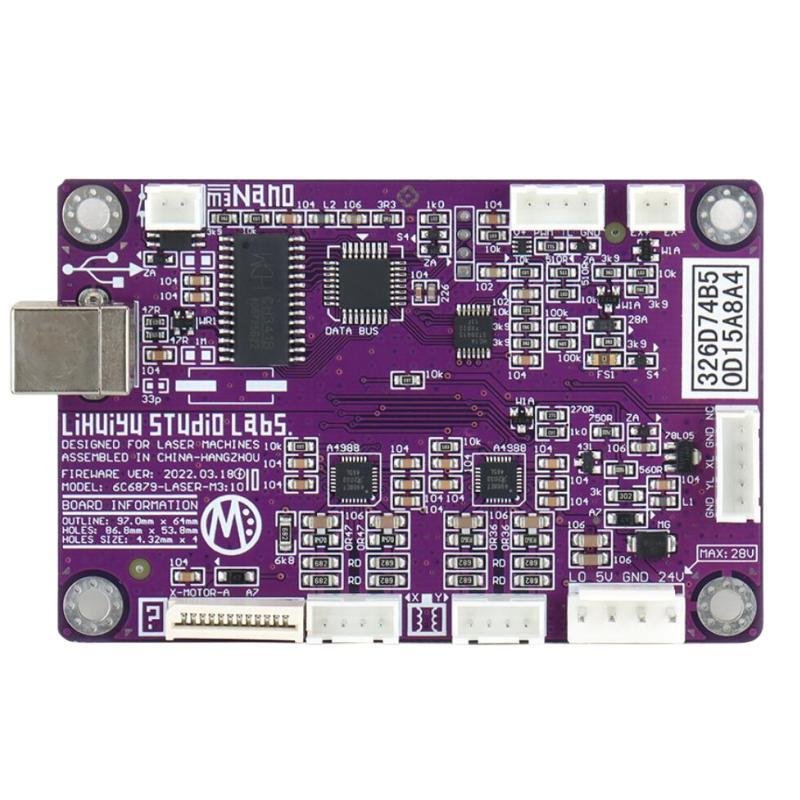

CO2 laser is the most commonly used type of laser equipment. The reason why CO2 machines are called CO2 machines is because they use laser tubes containing a mixture of carbon dioxide, nitrogen, and helium. The working principle of laser is to generate a 10.6-micron beam, which will heat the material until it evaporates. They can cut objects as small as 0.1 millimeters. CO2 machines have a wide range of materials that can be cut, such as non-metallic materials, making them widely used.

CO2 lasers are increasingly being used in industries such as woodworking, packaging, textiles, and automobiles. Although CO2 equipment is the slowest among the three types and requires regular maintenance, this fact is easily offset by the versatility provided at low cost. Another reason why CO2 machines are so popular is their different workspaces and relatively affordable prices. CO2 machines can be installed in any workspace.

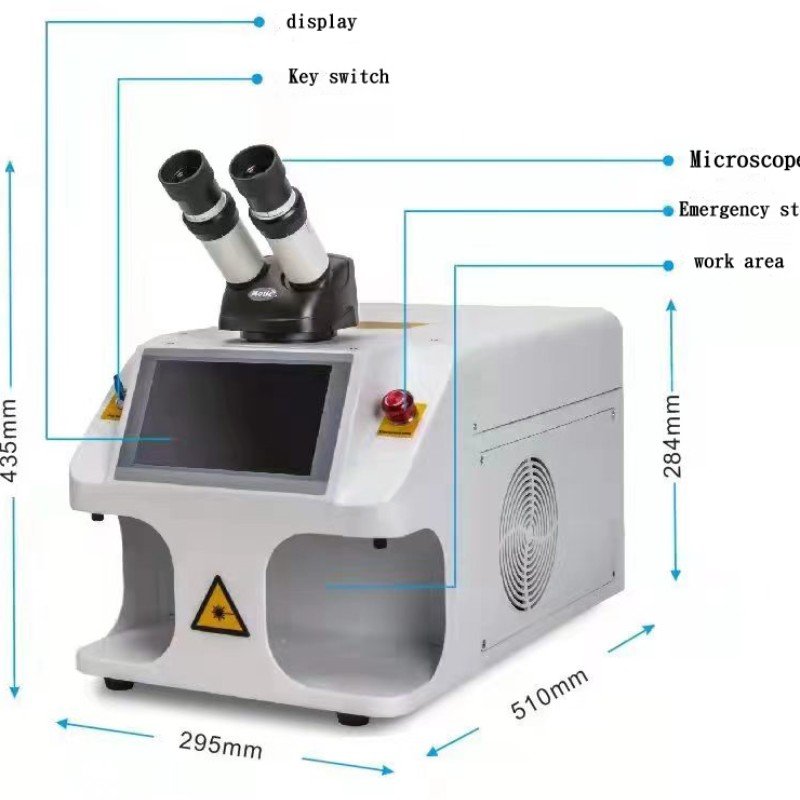

UV laser machine

UV laser machines are very similar to fiber laser machines. They are built using ultraviolet solid-state drives. The wavelength generated by ultraviolet radiation is one-third of the wavelength of fiber optic engraving machines, allowing them to produce finer details. UV laser machines can engrave the same materials as fiber lasers, as well as some organic materials such as wood. UV uses a special method called “cold processing” to reduce the heat generated during the carving process, thereby reducing the risk of material deformation.

These characteristics make ultraviolet radiation highly sought after by individuals in the fields of electronics, aerospace, and healthcare. Due to the newer nature of UV machines, they are usually the most expensive among these three types of machines. In addition, due to its relatively new applications, ultraviolet lasers only offer three possible wattages: 3 watts, 5 watts, and 10 watts.

CO2, Fiber, and UV machines are excellent tools for cutting and carving materials. Each of them has their own strengths and weaknesses, which makes them attractive to various clients. CO2 machines are quite affordable, while Fiber and UV machines are considered worth investing in growth industries. Not sure which machine is suitable for you, please check out our laser equipment. We also provided a video to get more help